About Us

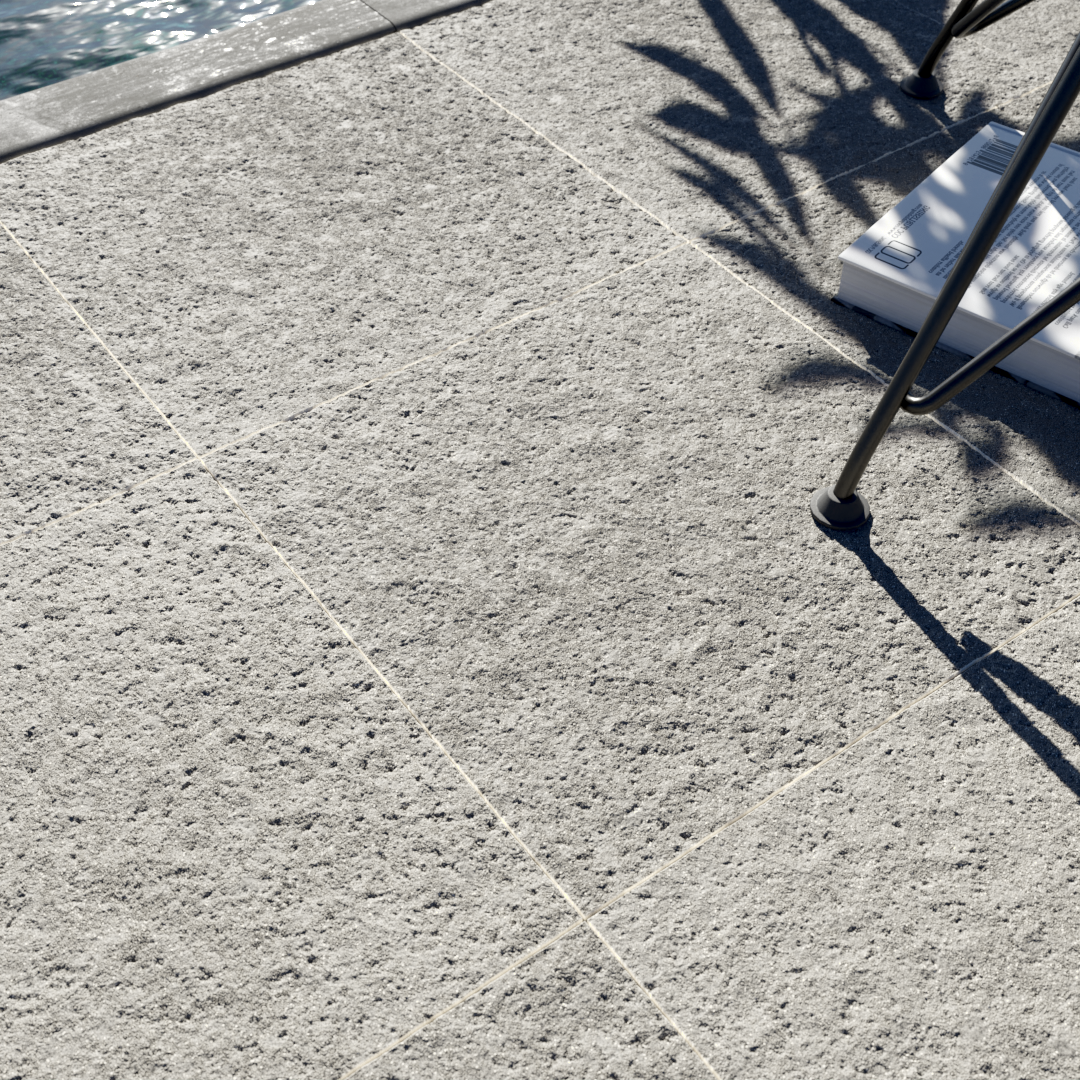

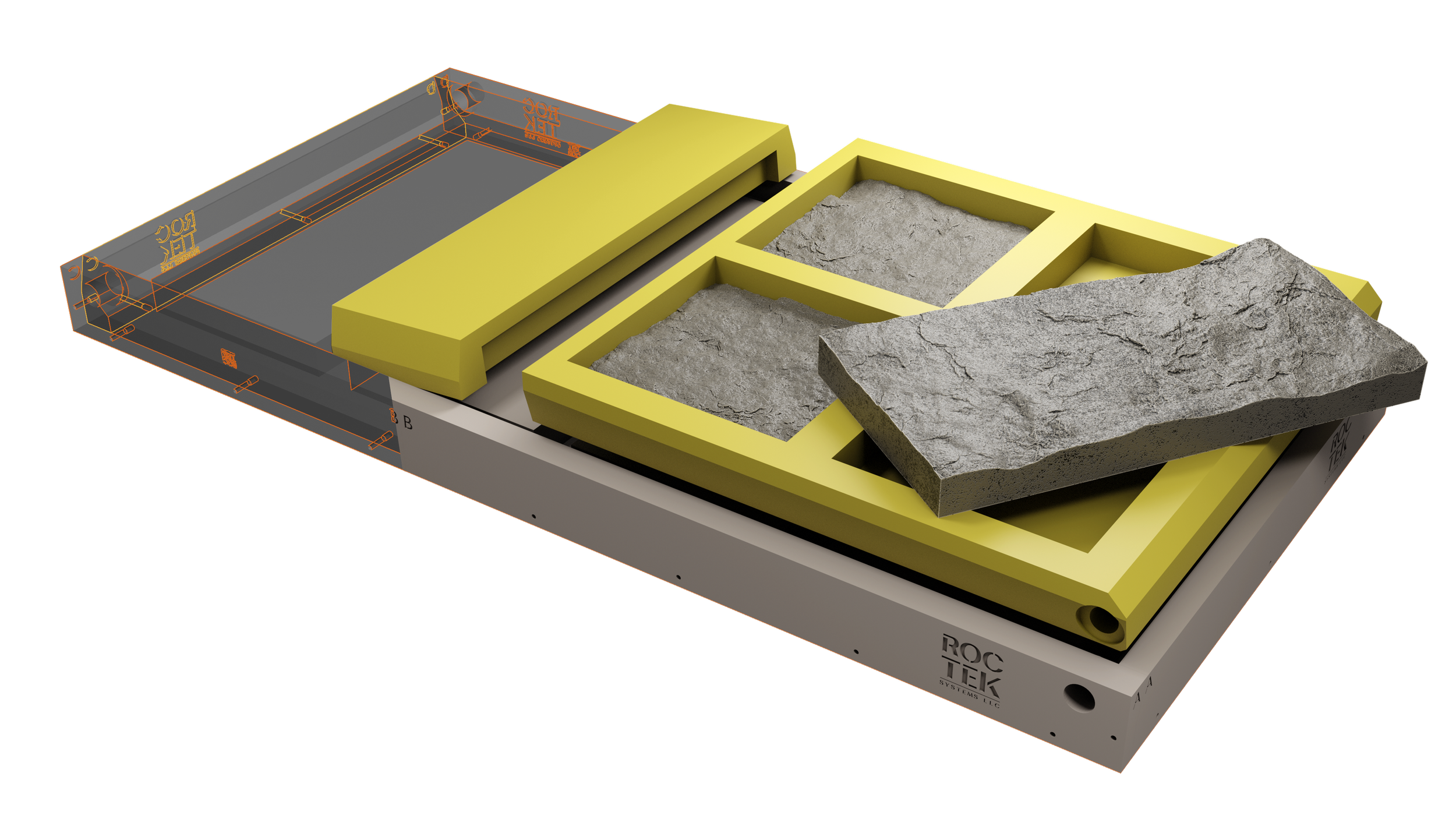

At RocTek, we specialize in the design and 3D printing of molds for concrete products and textures. Our team of experts has extensive experience in the industry and is dedicated to providing innovative solutions to meet our clients' unique needs. With our cutting-edge technology and advanced software, we can produce high-quality custom molds quickly and efficiently. We take pride in our ability to offer cost-effective and sustainable solutions for our clients. At RocTek, we are committed to providing outstanding customer service and delivering exceptional products that meet or exceed our clients' expectations.

FAQs

How accurate are 3D-printed molds, and what is their dimensional stability?

Overall, with the right materials, design, and post-processing, 3D printed molds can achieve a high level of accuracy and dimensional stability, making them a great option for wetcast mold-making.How long does it take to print a mold, and what factors affect the printing time?

In general, smaller and less complex molds can be printed in a shorter amount of time, while larger and more complex molds may take several hours or even days to print.

Are 3D-printed molds cost-effective compared to traditional mold-making methods?

One advantage of 3D-printed molds is that they can be quickly and easily produced without the need for expensive and time-consuming mold-making processes. Traditional mold-making methods, such as casting or machining, can be time-consuming and require specialized equipment and skills.

What is the process for designing a mold using 3D printing?

3D print the mold: Once the design is complete, the mold can be 3D printed using a suitable printing material. It's important to choose a material that can withstand the pouring of the rubber skin and can produce a surface texture that will transfer to the final product.